Top Industrial Fruit Concentrate Equipment for 2025

As the global demand for fruit juice concentrates continues to soar, 2025 marks a turning point in technological innovation and processing efficiency. In this comprehensive guide, we review the top industrial fruit concentrate equipment dominating the market this year. From high-capacity evaporators to cutting-edge aseptic filling systems, the following technologies are engineered to deliver superior product quality, maximum yield, and compliance with the most stringent international food safety standards.

1. High-Efficiency Falling Film Evaporators

Unmatched Thermal Efficiency and Gentle Product Treatment

The falling film or Circulation force evaporator remains the gold standard in fruit concentrate production due to its low residence time, making it ideal for heat-sensitive fruits like passion fruit, pineapple, and mango. Leading manufacturers like Tropical Food Machinery Srl, and GEA have released upgraded 2025 models featuring:

- Multi-effect evaporation systems for reduced steam consumption

- Automatic cleaning-in-place (CIP) and descaling cycles

- Vacuum-assisted evaporation for preserving aroma and nutrients

- Titanium and stainless steel heat exchangers for corrosion resistance

These evaporators ensure higher brix levels with minimal degradation of color, flavor, and nutrients—critical for premium tropical concentrates.

2. Tubular and Plate Heat Exchangers

Precision Heating and Cooling in a Compact Footprint

Essential for pasteurization and thermal treatment, these systems have been redesigned in 2025 with smarter flow dynamics and energy recovery loops. The most sought-after features include:

- Automated temperature control with PLC integration

- Hygienic weld-free design to minimize microbial risks

- Modular build for scaling up production lines

- Dual-section exchangers for both heating and cooling

Applications span across passion fruit, guava, orange, and even sensitive fruit purées like banana and avocado blends.

3. Decanter Centrifuges and Disc Stack Separators

Solid-Liquid Separation for Purity and Yield Optimization

A critical stage in clarifying fruit juice before concentration, modern separators from Flottweg, SPX Flow, and Westfalia now offer:

- Fully automatic operation with viscosity-adaptive controls

- Self-cleaning bowls for continuous operation

- High g-force capability to process fibrous tropical fruits

- Compact footprints for space-saving integration

These systems guarantee up to 99.5% clarification efficiency, enabling the next stages of filtration and evaporation to function at peak performance.

4. Enzymatic Hydrolysis Systems

Enhanced Juice Extraction and Clarification

For challenging raw materials like pomegranate, tamarind, or guava, enzymatic treatment has proven indispensable. The 2025-generation enzymatic systems boast:

- Precise dosing pumps and automatic mixing tanks

- Temperature-controlled reaction chambers

- Real-time monitoring of enzyme activity levels

- Food-grade, corrosion-resistant components

By breaking down pectins and complex cell walls, these units boost juice yield by 10–20% and reduce filtration load downstream.

5. Ultrafiltration and Crossflow Membrane Systems

Advanced Juice Clarification and Aroma Recovery

Membrane technology continues to evolve, and the latest ultrafiltration units from Pentair, Tetra Pak, and Pall Corporation now offer:

- High-flux membranes with anti-fouling coatings

- Fully automated cleaning cycles with integrated CIP

- Selective separation of aroma volatiles for retention

- Reduced water and chemical consumption per cycle

These systems are critical for high-end clear concentrates, particularly for citrus and apple base products intended for export.

6. Aseptic Bag-in-Drum Filling Machines

Preserving Product Integrity Without Cold Chain

The final link in the production chain, aseptic fillers ensure microbial stability and extended shelf life. Top-performing fillers in 2025 now feature:

- Fully servo-driven filling heads for ultra-precise volume control

- Integrated sterilization of spouts, caps, and bags

- Steam-assisted, closed-loop systems for ultra-clean filling

- Bag-in-box, bag-in-drum, and IBC container compatibility

Manufacturers like Baginco, Tropical Food Machinery Srl, and Della Toffola lead the charge with models capable of up to 1,500 liters/hour per head, with zero contamination risk.

7. Smart Process Automation & IoT Integration

Digitalization of Fruit Processing Lines

2025 is the year smart factories become the new norm. Automation platforms from Siemens, Rockwell, and Schneider Electric are embedded across fruit concentrate lines, delivering:

- Real-time production monitoring via SCADA dashboards

- Predictive maintenance alerts to avoid downtime

- Automated traceability and compliance reporting

- Remote equipment diagnostics and control

These integrations dramatically reduce labor requirements and improve overall equipment effectiveness (OEE), making them a game-changer for competitive processors.

8. Belt Presses and Hydraulic Extractors

Maximizing Juice Recovery from Pulpy and Fibrous Fruits

Specialized mechanical extraction equipment plays a pivotal role in squeezing the most out of difficult-to-process fruits like papaya, mango, and lychee. The best 2025 models offer:

- Multi-stage pressing with pre-heating options

- Pneumatic tension control for belt stability

- Minimal oxidation design to preserve phenolic compounds

- Simple disassembly for sanitation and maintenance

These rugged machines can recover up to 90% of total juice content, significantly lowering raw material costs.

9. Aroma Recovery Systems

Capturing the Essence of Fresh Fruit

To cater to the high-end beverage market, aroma recovery units are indispensable. The most advanced systems now combine:

- Vacuum distillation columns with multi-level condensing stages

- Closed-loop recovery of flavor-rich volatiles

- Integration with evaporator systems for seamless aroma capture

- FDA- and EU-compliant materials for food-grade operation

These systems allow manufacturers to re-inject natural aromas into concentrates, differentiating their products in crowded international markets.

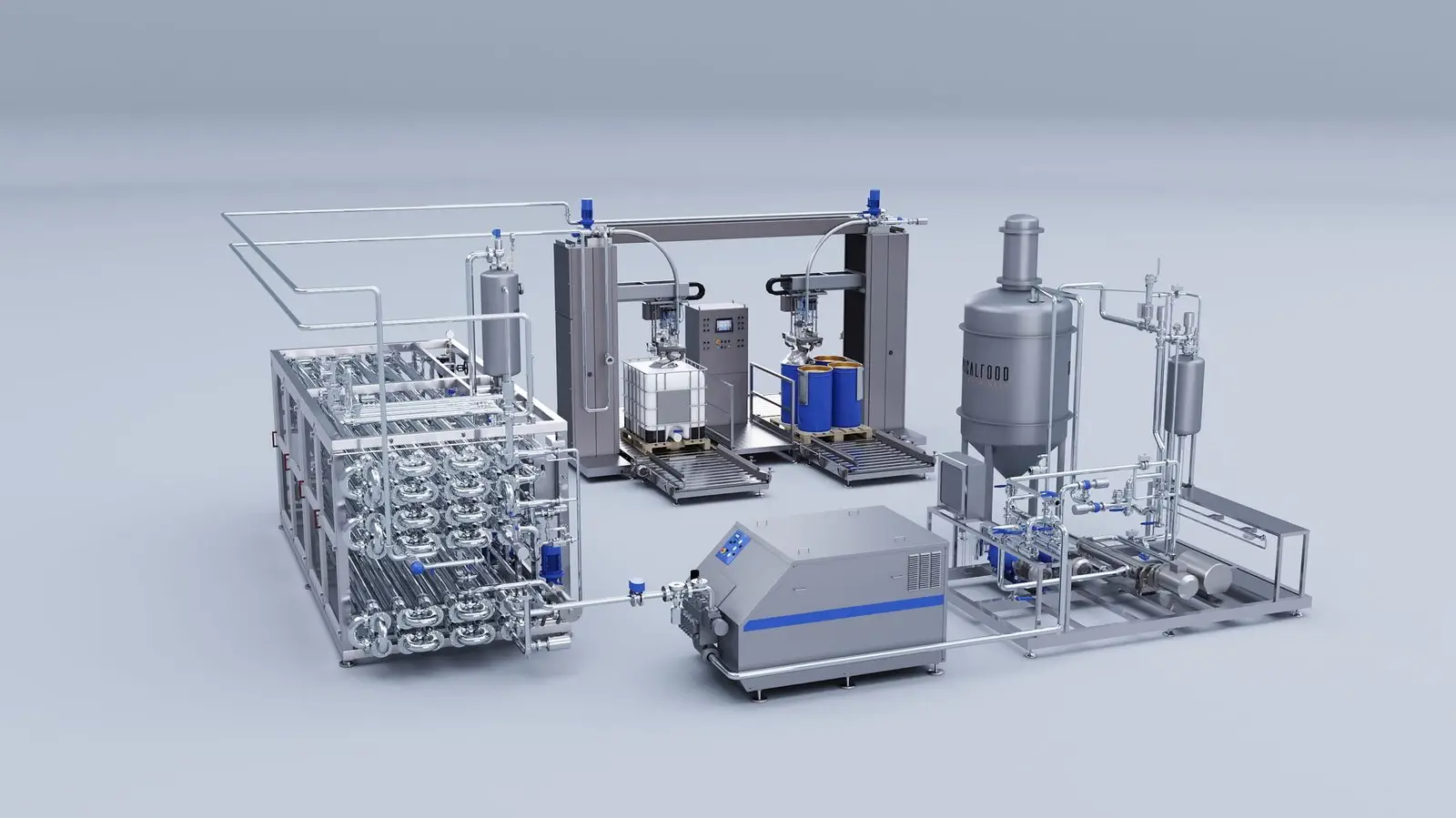

10. Turnkey Fruit Processing Lines

All-in-One Modular Solutions for Greenfield Plants

For investors and processors expanding in 2025, turnkey solutions offer the fastest route to market. Leading integrators like Tropical Food Machinery Srl now provide:

- End-to-end lines from washing to aseptic packaging

- Custom design for local fruit varieties and climate conditions

- CE-certified equipment with rapid installation timelines

- Full operator training and post-installation support

These setups are tailored for scalability, enabling operators to start with 5–10 tons/hour capacity and expand as market demand grows.

Conclusion: Invest in Next-Gen Fruit Concentrate Technology

The year 2025 has ushered in a new era of automation, sustainability, and product quality in the fruit concentrate industry. Whether you’re upgrading an existing plant or planning a greenfield facility, investing in the right equipment ensures long-term competitiveness, regulatory compliance, and market growth.

From falling film evaporators to IoT-driven automation, these innovations are reshaping how we extract, preserve, and export the essence of tropical fruit to the world.

0 Comments