Leading Manufacturers of Tropical Fruit Processing Machinery

In the fast-evolving world of tropical fruit processing, only a handful of manufacturers stand at the pinnacle of engineering excellence, technological innovation, and global trust. These companies are not just equipment suppliers—they are strategic partners driving the modernization of fruit processing plants worldwide. From passion fruit and mango to pineapple, guava, and lychee, their machines are designed to handle the complexities and richness of tropical fruits with maximum efficiency and product quality.

Below is a curated list of the most reputable manufacturers of tropical fruit processing machinery leading the market in 2025.

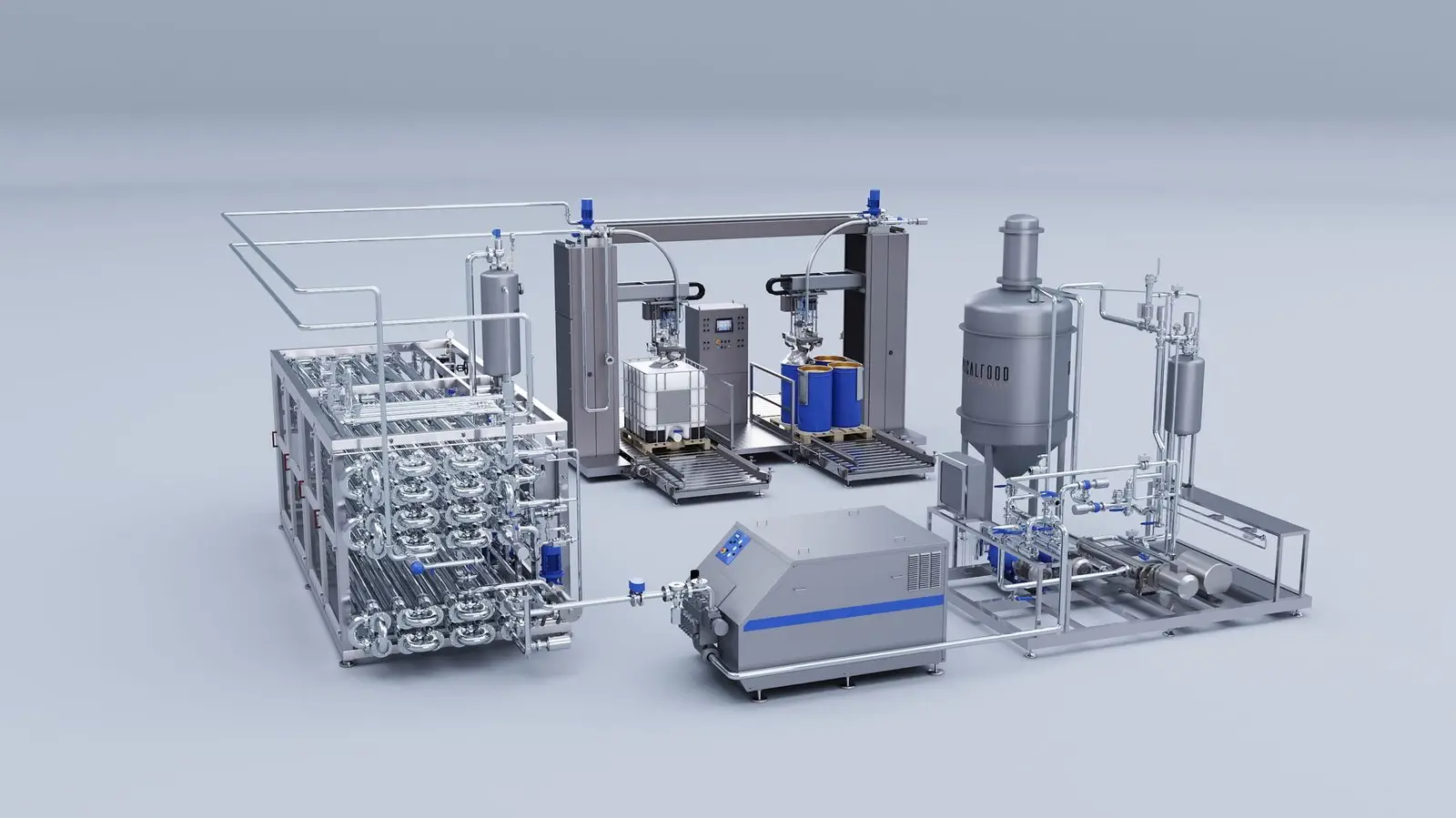

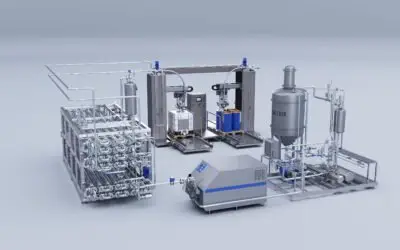

1. Tropical Food Machinery (Italy/Brazil)

Custom Solutions for Exotic Fruit Processing

With facilities in both Italy and Brazil, Tropical Food Machinery Srl merges European engineering with South American expertise. Known for their deep experience with exotic tropical fruits, they offer comprehensive lines for juice, concentrate, and frozen purée production.

- Key Strengths: Flexible capacity ranges (from 500 kg/h to 20 tons/h), adaptable to seasonal crops

- Technologies: Thermal processing, belt presses, aroma recovery

- Highlight: Unrivaled know-how in pineapple, papaya, and passion fruit processing

And The Tropical Food Machinery Srl had sold some complete plants of passion fruit processing in Vietnam.

2. FENCO Food Machinery (Italy)

Reliable Engineering for Large-Scale Fruit Processing

FENCO specializes in building large-scale fruit and vegetable processing plants, with an emphasis on automated, continuous production lines. Their technology focuses on achieving high yield with minimal product degradation—essential for tropical fruit concentrates and NFC juices.

- Key Strengths: Complete integration from receiving to packaging

- Core Technologies: Decanter centrifuges, plate heat exchangers, aseptic fillers

- Highlight: Deep experience with mango, guava, banana, and citrus fruits

3. GEA Group (Germany)

Engineering Precision at an Industrial Scale

GEA is a global powerhouse offering advanced liquid food processing systems, especially in evaporation, separation, and hygienic filling. Their automation platforms and energy-efficient designs make them a preferred choice for sustainable tropical fruit factories.

- Key Strengths: Falling film evaporators, membrane filtration systems

- Innovation: Integration of digital twins and IoT monitoring in fruit lines

- Highlight: Customizable systems for both clear and cloudy concentrates

4. Alvan Blanch (United Kingdom)

Compact, Cost-Effective Fruit Processing Solutions

Catering especially to emerging markets and small-to-mid scale operations, Alvan Blanch offers modular units for fruit washing, pulping, and juice extraction. Their systems are highly mobile, durable, and easy to operate—even in remote areas.

- Key Strengths: Mobile fruit processors, multi-fruit extractors

- Target Clients: SMEs, cooperatives, agro-export startups

- Highlight: Ideal for Africa, Southeast Asia, and Caribbean market needs

5. JBT Corporation (USA)

Global Innovators in FoodTech and Aseptic Technology

JBT is a recognized name in aseptic processing, especially for fruit juices, purées, and smoothies. Their UHT sterilization and aseptic fillers are used in the world’s largest juice brands, ensuring shelf-stable tropical products with no preservatives.

- Key Strengths: SteriFlow UHT systems, AsepTec fillers, intelligent packaging lines

- Industries: Beverage multinationals, OEM production

- Highlight: Their aseptic technology is FDA and EU compliant, ideal for export-oriented production

6. Alfa Laval (Sweden)

Efficiency-Driven Processing Solutions

With deep roots in thermal and fluid handling, Alfa Laval offers high-efficiency heat exchangers, decanters, and separation systems vital to tropical fruit processing. Their sanitary design and energy optimization tools ensure long-term operational savings.

- Key Strengths: Pasteurization, juice clarification, evaporation

- Clients: Juice processors, industrial food groups

- Highlight: Specialized solutions for multi-fruit factories producing both tropical and temperate fruits

7. CFT Group (Italy)

Innovation Meets Integration

CFT Group delivers smart, automated processing solutions with flexibility across various tropical fruits. Their machines are built for long operational life with minimal downtime. Integration with SCADA and MES platforms gives processors full control and traceability.

- Key Strengths: Tubular sterilizers, rotary vacuum filters, enzymatic maceration

- Technologies: High-speed filling, de-pulping, enzymatic pre-treatment

- Highlight: Compact solutions for pomegranate, mango, and lychee

8. Flottweg SE (Germany)

Leaders in Separation and Clarification

For operations that prioritize juice purity and extraction yield, Flottweg offers cutting-edge decanter centrifuges and separators. Their systems ensure clear juice separation from pulpy tropical fruits, minimizing waste and maximizing revenue.

- Key Strengths: Tricanter®, Sedicanter®, disc stack separators

- Industries: Premium juice, baby food, concentrate exports

- Highlight: Plug-and-play options for easy retrofitting into existing lines

9. Zumex Food Engineering (Spain)

Premium Juice Extraction with High-End Design

While widely known for their commercial juicers, Zumex also designs industrial fruit extraction solutions tailored to food service, supermarket chains, and medium-scale processors. Their sleek design meets food safety in a seamless way.

- Key Strengths: Whole-fruit extraction, citrus processing lines

- Segments: Fresh juice retailers, hotels, mid-size juice plants

- Highlight: Integrated peel separation systems with minimal labor

Conclusion: Choosing the Right Manufacturer for Your Tropical Fruit Operation

The success of your tropical fruit processing project depends on partnering with manufacturers who combine technical mastery, local customization, and reliable after-sales support. Whether you’re building a greenfield facility, upgrading your concentration line, or entering the export juice market, these industry leaders offer the tools and expertise to deliver consistent quality, efficiency, and profitability.

0 Comments