How Passion Fruit Concentrate Is Made: Inside the Processing Line

Passion fruit is more than just a tropical delicacy—it’s a vibrant, aromatic treasure used in juices, beverages, yogurts, desserts, and even savory sauces. But behind that golden, tangy concentrate lies a meticulously engineered processing line designed to preserve the fruit’s natural flavor, color, and nutritional richness. In this article, we open the doors to the inner workings of a modern passion fruit processing plant, revealing every crucial step that turns fresh fruit into shelf-stable concentrated passion fruit juice ready for global export.

1. Raw Material Reception and Quality Inspection

It all begins with the arrival of freshly harvested passion fruits at the processing facility. These fruits are typically delivered within hours of harvest to preserve freshness and minimize spoilage.

- Sorting conveyors remove leaves, sticks, and foreign materials

- Visual inspection and digital scanners grade fruit based on ripeness and size

- Rejected fruits (overripe, underripe, or damaged) are separated to ensure only prime-quality fruit enters the line

This step ensures that only the most flavorful and aromatic fruits make it into the final concentrate, setting the foundation for a premium product.

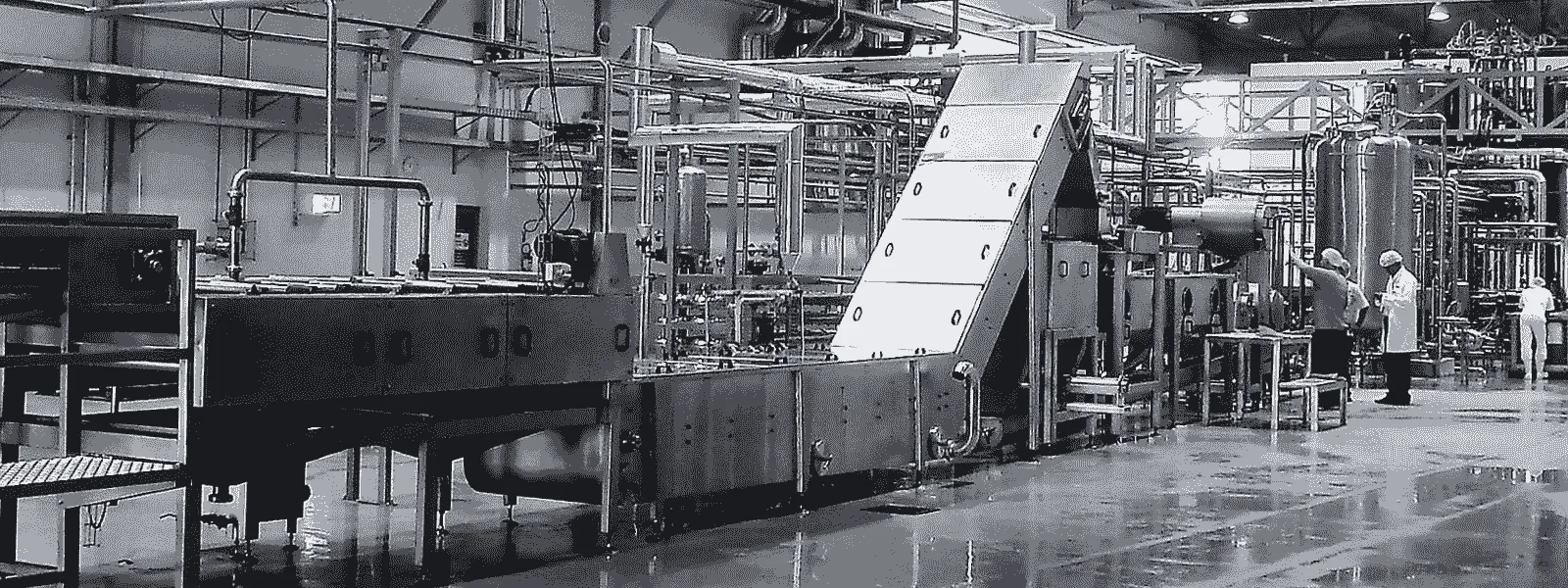

2. Washing and Sanitization

Next, the selected fruits undergo a thorough multi-stage washing process to eliminate dirt, pesticide residues, and microbial contaminants.

- Rotary drum washers or bubble washers agitate the fruit gently with water and food-grade sanitizers

- Spray bars and brushes scrub the skin surface

- Final rinsing with chlorine-free treated water ensures cleanliness before processing

Maintaining high hygienic standards is vital to comply with HACCP and FDA regulations, especially for products intended for export.

3. Pulp Extraction and Seed Separation

Passion fruit is unique—it has a hard outer shell and a gelatinous, seed-filled pulp that must be carefully extracted.

- Mechanical cutters or crushers break the fruit open

- The contents are then fed into pulpers and deseeders, which separate juice sacs from the shell and sieve out the hard seeds

- The remaining pulp is collected as passion fruit juice with pulp—a raw, vibrant blend full of aroma and flavor

Depending on product requirements, some processors may retain a percentage of pulp or remove it entirely for a clear juice concentrate.

4. Enzymatic Treatment (Optional)

For clearer juice and improved extraction efficiency, enzymes such as pectinase may be added at this stage.

- The enzymatic reaction breaks down complex polysaccharides and pectins

- This process enhances juice yield, reduces viscosity, and facilitates downstream filtration

- Temperature-controlled tanks maintain optimal enzyme activity levels

This step is often used when producing clear passion fruit concentrate or blending with other fruit bases.

5. Juice Clarification and Filtration

To ensure a smooth, sediment-free product, the juice is clarified using:

- Decanter centrifuges to separate fine solids and fibers

- Ultrafiltration membranes to remove haze-forming particles

- Crossflow filters for sterile and continuous operation

This stage creates a brilliant, stable juice base, free from suspended solids, ready for concentration.

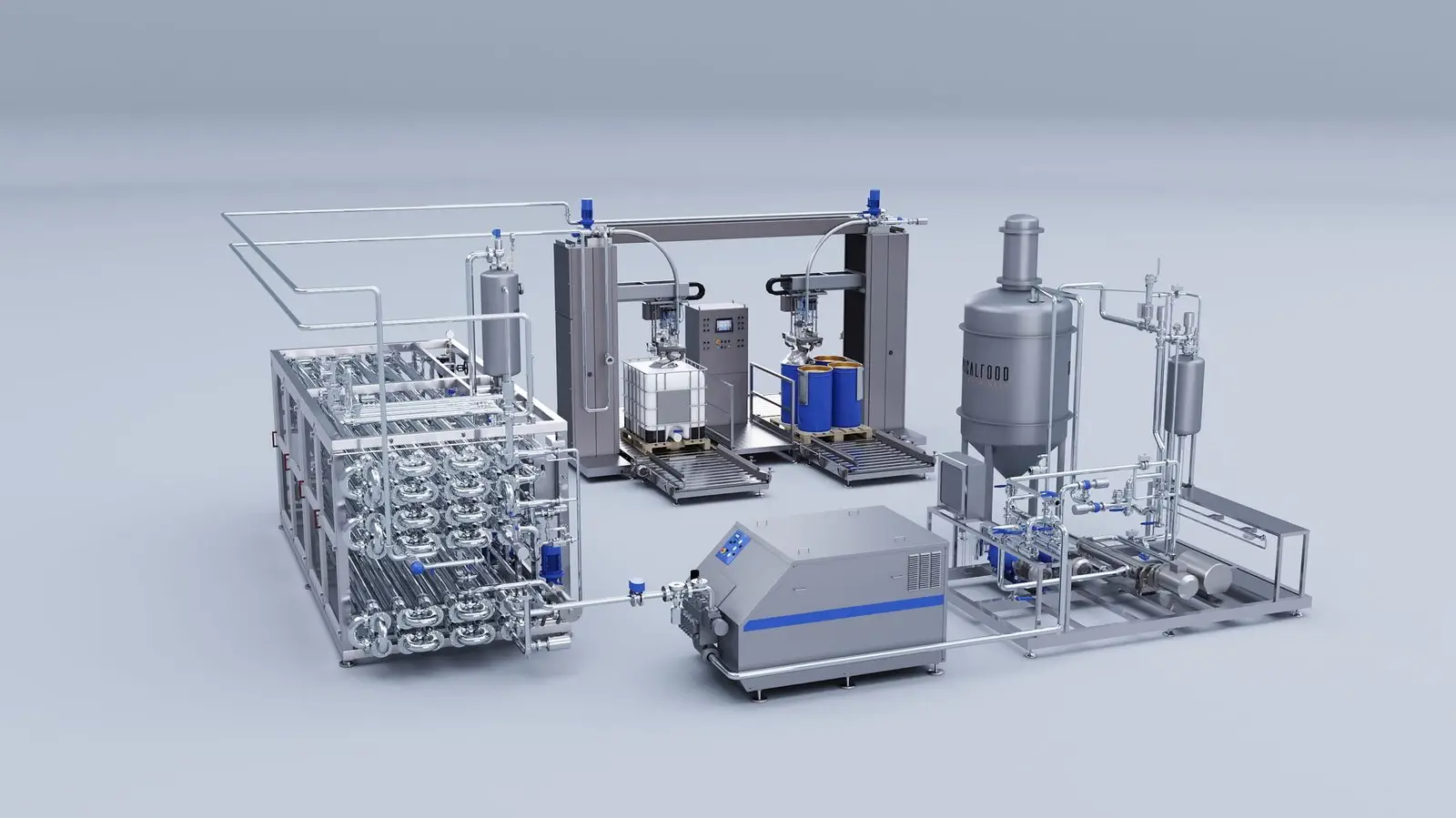

6. Evaporation: Concentrating the Juice

At the heart of the operation lies the force circular evaporator – a system that removes water from the juice while preserving its flavor and nutritional content.

- Juice enters the evaporator under vacuum pressure to lower the boiling point, minimizing thermal damage

- Water is evaporated in multiple effects, increasing energy efficiency

- The result is a thick, aromatic concentrated juice with Brix levels ranging from 45–50°, depending on customer specs

Some systems also include aroma recovery units, which trap volatile compounds and reintegrate them back into the concentrate for superior flavor retention.

7. Pasteurization and Deaeration

To extend shelf life and ensure food safety, the concentrate is then pasteurized:

- High-temperature short-time (HTST) pasteurization destroys pathogens without harming taste

- Deaerators remove oxygen, preventing browning and nutrient loss

- The process is tightly controlled with PLC and SCADA systems to ensure consistency and compliance

This thermal treatment prepares the concentrate for long-term storage or immediate packaging.

8. Aseptic Filling and Packaging

Once pasteurized, the passion fruit concentrate is directed to aseptic filling lines, where it is packed under sterile conditions to maintain freshness without preservatives.

- Packaging options include bag-in-drum, bag-in-box, or IBC totes

- Steam sterilization of spouts, bags, and valves ensures zero contamination

- Products is filled automatically, sealed, and labeled for traceability

This step locks in the flavor and aroma, ensuring the concentrate remains shelf-stable for up to 18–24 months without refrigeration.

9. Cold Storage and Dispatch

Finished products are either shipped immediately to distributors or stored under temperature-controlled conditions awaiting export.

- Warehouse systems use barcode tracking and batch control for inventory management

- Products are grouped by destination, Brix, and packaging type

Most passion fruit concentrate is destined for beverage companies, ice cream manufacturers, jam producers, or food service providers worldwide.

10. Quality Assurance and Laboratory Testing

Throughout the process, rigorous quality control protocols are implemented to guarantee product integrity:

- Brix testing to verify concentration levels

- Microbial analysis to ensure food safety

- Sensory evaluation for taste, aroma, and color

- Heavy metal and pesticide residue checks for export compliance

Only batches that meet all specifications receive certification and export clearance.

Conclusion: A Blend of Nature and Innovation

Making passion fruit concentrate is more than a technical process—it’s a delicate balance of preserving the essence of nature while embracing the precision of modern engineering. Every step, from fruit reception to aseptic packaging, is designed to deliver a final product that is bold, consistent, and market-ready.

In 2025, with rising global demand and tightening food safety standards, processors who invest in state-of-the-art technology, traceability systems, and quality control will lead the way in delivering premium tropical concentrates to the world.

0 Comments